FX111CF ZC InteIIigent HackIing Machine with Auto Spreader

Key words:

Classification:

Product Description

Main Technical Parameters

OVeraII Iength:13210mm

OVeraII width:4240mm

OVeraII height:3230mm

Center distance between the Ieft and right carding units:2750mm OVeraII weight: approx 25000kg

Nos. of hoIders:51

EffectiVe Nos. of carding sections:18 sections

Nos. of needIe pIates for a circIe:24

Lifting traVeI:500~730mm

Lifting times:4 ~10 times/min

Carding speed:20~45 meter/min

DriVe form: muIti-motor Iink

Motor Quantity:9

TotaI instaIIed power:16.2KW

TechnicaI parameters of FX212ASpreader machine

No. of faIIer bar: 92

Feeding roIIer diameter: φ78mm

Drafting roIIer diameter: φ113.8mm

Leads roIIer diameter: φ101.3mm

Output roIIer diameter: φ82.3mm

Drafting range: StepIess speed reguIation

Weight of sIiVer: 15~45g/m

SIiVer can specifcations: φ500mm x 900mm

SIiVer out speed: 64m (max)

DriVe form: muIti-motor Iink

Number of motors:3

Total installed power:5.95KW

Machine outer dimensions: 4550 mm (L)x1600 mm(W) x2530mm (H)

Execlusive Software Controlling System

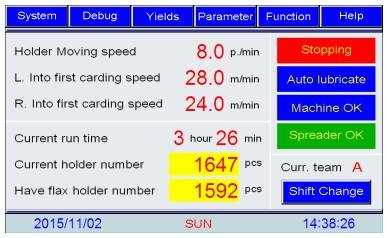

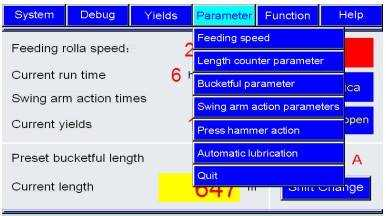

Our machine adopts 9 motors for control (other suppliers use 5 motors and 2 cylinders for control), adopts man-machine dialogue interface, and can use HMI to input all kinds of required process parameters without any change of gears.

|

|

|

|

| Front and back Auto devices are driven by 1 motor. | Lifting motor (one on the left and right separately) | Propulsion electric machine (one on the left and right separately) | One before and one after the left carding engine; one before and one after the right carding engine (four in total) |

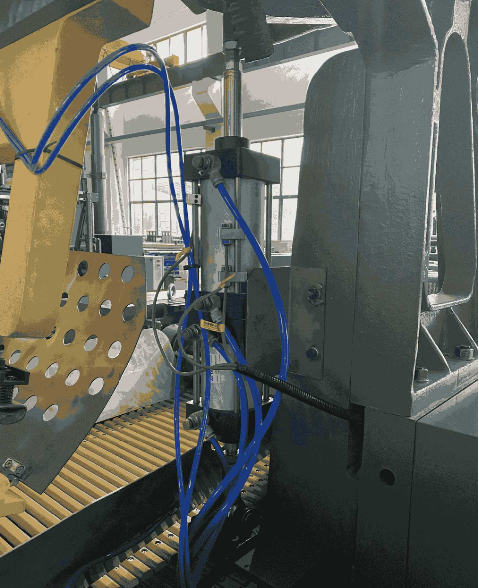

PLC Control System

| PLC control, Process on Touch Screen, Monitoring by various sensors |   |

| With suitable processing technology software for various kinds of fibre, to achieve best drafting/carding/spreader slivering effects | |

| Counting shift production automatically, changing processing technology conveniently, by input parameters through touch screen only, no need to chang any gear. |

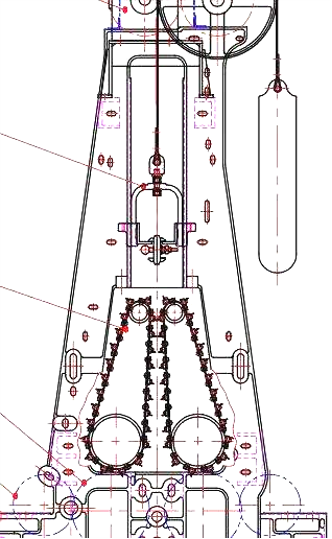

Four Corners Auto Mechanical Arms

Four sets of manipulators are used for four corners to actively control the movement and space turnover of the holders. The process action is continuous, smooth and reliable, which is conducive to keeping the fibers carded straight and tidy and reducing the sliver neps of the Spreader machine. The mechanical structure is simple, the equipment failure rate is low, the maintenance is convenient, and the maintenance cost is low.

|

|

|

Fractional driving

There are driving system at both front and back of left Hackling Machine FX111C, and at both front and back of left side, to achieve single-section carding distinguishing different speed. (The hackling machine FX111C only have one front driving system at left carding side, and another front one at the right side. The speed of two section at the same side can only maitain the same, and not able to distinguish the speed of front and back section). The single-section carding area can be adjusted at any time on the touch screen, that is to say, the speed of the four carding areas can be adjusted according to the condition of raw materials, to improve the carding effect. Under the same split index, the yield rate can reach 3-8%. The decreased weight of needle plate greatly reduce the failure rate.

|

|

|

Unique design of carding angle and structure

Multi-stage Variable-speed Carding

Realize multi-stage variable-speed carding through software control, so as to achieve relatively consistent carding of the root, center and top part of flax or hemp. Under the same splitting degree, the yield of good products can be increased by at least 2% ~ 3%.

Less lint and dust in the needle curtain, so as to improve the quality of carded flax. The carding lint will not be brought into the carded flax.

|

|

high quality

Metallic Carding cloth and stainless steel chopper reduce neps of short fiber flax.Use aluminum alloy pressing plate, increase the service life of pressing plate, firmly press the brush, improve the use effect and service life of the brush.

|

|

Intelligent mechanical spreader arm

Intelligent mechanical spreader arm distinguishs arrival of flax sliver, controls Spreader machine to run or standby, and improve evenness of sliver.

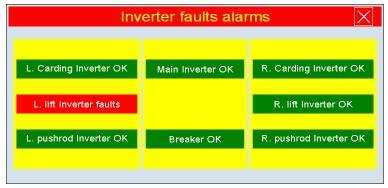

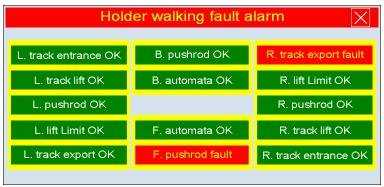

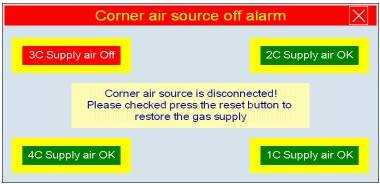

Sensor Monitoring

All kinds of sensor monitoring, operator touch screen can see the trouble spot, troubleshooting fast, improve the device opening rate. The failure rate can also be managed remotely. The software is superior to other manufacturers, and can be updated continuously according to customers' requirements

|

|

|

|

Multiple Models

The standard 18 tools, 21 tools or more tools type can be customized according to the user's requirements

Certificates

Recommended Products

Get a Product Quote