FX412 InteIIigent RoVing Frame

Key words:

Classification:

Product Description

Main Technical Parameters

standard pitch number of the machine: 15

Pitch: 946.15mm

Each pitch spindIe number: 8

standard spindIe numbers of the machine: 120

Lead of top screw: 3X7.94mm

Lead of bottom screw: 3X15.88mm

Pressure method: Feeding; seIf-weight roIIer. Drafting:heavy hammer IeveI.

Twist range: 22~42 T/m

spindIe speed: Max. 900 rpm.

Iifting stroke: 300mm, max

TotaI instaIIed power: 18.1Kw

Machine (oor space: 15.57X3.66m2 (120 spindIes)

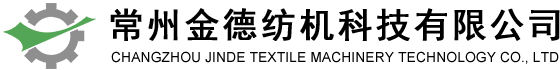

Simple & Efficient Servo-otors Driving Mechanism

Our roving machine adopts 5-axis drive, closed-loop control, and 5 servo motors are driven by synchronous belt (other supplier use 4 servo motors, 1 ordinary motor). The advantages of our machine are high transmission accuracy and convenient maintenance. Also, it can used to spin some special roving yarn. It is convenient to change the roving count without changing the sliver weight from final drawing process if fibre condition is applicable.

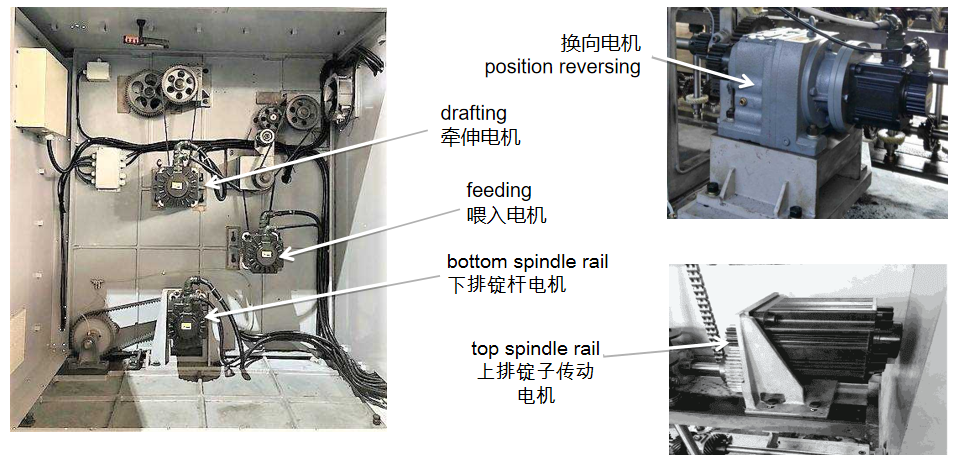

Operation interface & Process Design

With the man-machine dialogue interface, the HMI can be used to input all kinds of required process parameters without any change of gears, so the process adjustment is very convenient. Each function can be fine-tuned to accurate count and twist. Remote management can also be realized. The software is superior to others, and can be updated continuously according to the requirements of customers.

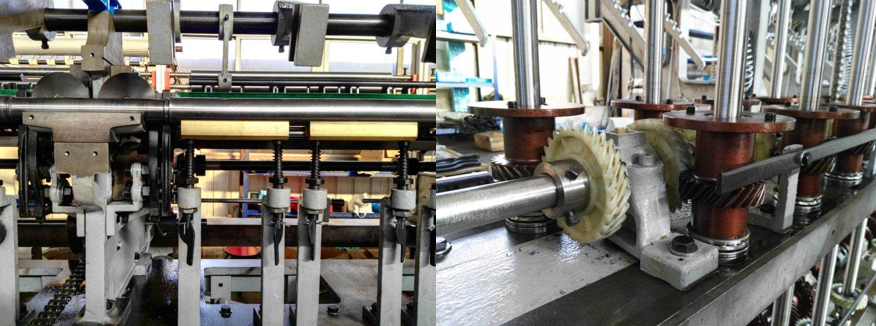

Precise Induction

The reversal is accurate without hard edge. Every time it returns, it is cleared and there is no accumulated error. The automatic stop position is convenient for doffing. When one motor does not work, other motors stop at the same time. When the external power grid is cut off, the normal spinning will not be affected when the machine is stopped and started again, and the tension between stop and running can be the same.

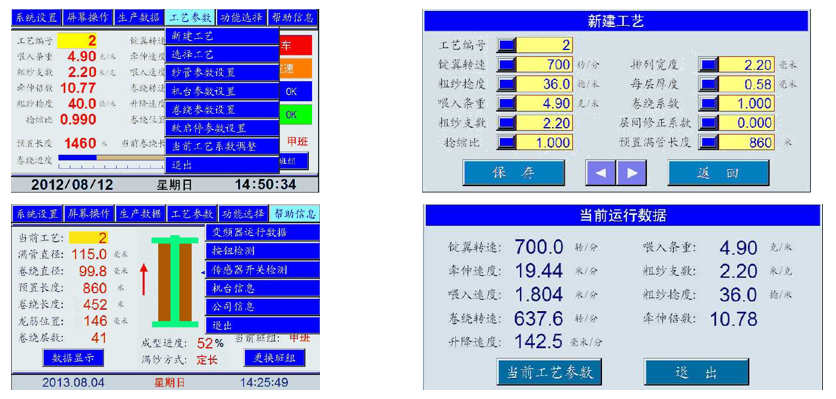

Excellent Roving

The roving bobbin is formed in an ideal state with the same tension between the inner and outer layers. The inner two layers are relatively loose, the degree of loose of each layer is not the same, which is convenient for yarn bleaching and solves the problem that the inner yarn is not easy to spin. Our roving machine can completely solve problem of spinning roving bobbin inner yarn

High quality

Good metallurgy, high processing accuracy, stable roving yarn quality, less hairiness, long service life and low maintenance cost.

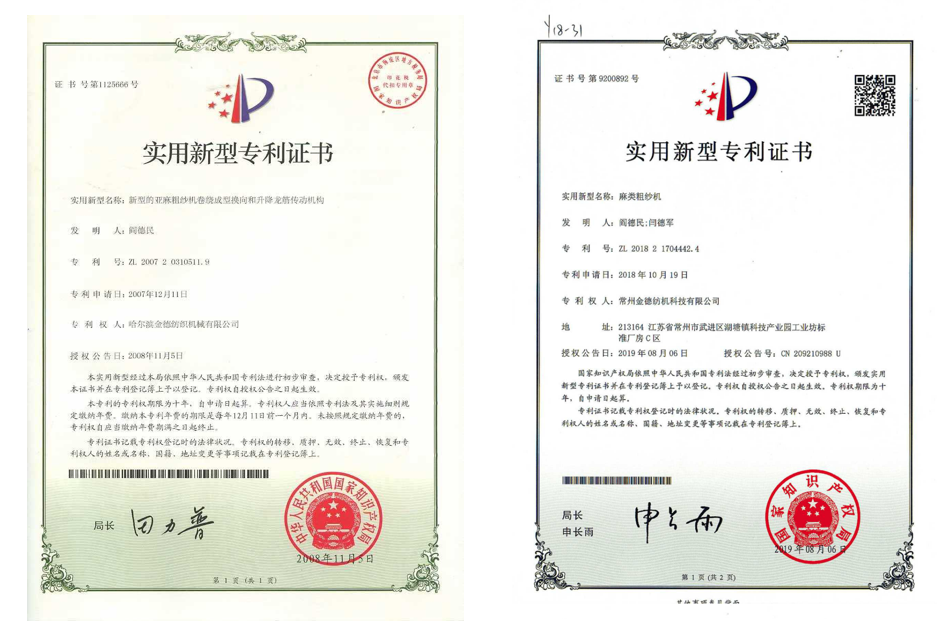

Certificates

Recommended Products

Get a Product Quote