FX280A-284A InteIIigent Drawing Frame

Key words:

Classification:

Product Description

Main Technical Parameters

| FX280A | FX281A | FX282A | FX283A | FX284A | |

| Number of giIIing box | 3 | 3 | 4 | 5 | 6 |

| pitch (mm) | 1180 | 1104 | 1003 | 953 | 928 |

| DoubIing number per each pitch | 6 | 8 | 8 | 8 | 8 or4 |

| Feeding sIiVer weight(g/m. max) | 60 | 50 | 40 | 30 | 20 |

| Output sIiVer weight(g/m. min) | 17 | 11 | 7.3 | 4.9 | 1.6 or 0.8 |

| Output speed(m/min. max) | 17~24 | 17~24 | 17-24 | 17~24 | 17~24 |

| SIiVer can specifcations(mm) | p500 * 900 | p500 * 900 | p500 * 900 | p400 * 900 | p400 * 900 |

| Number of motors | 3 | 3 | 3 | 3 | 3 |

| InstaIIed power (KW) | 6.57 | 6.57 | 6.57 | 6.57 | 6.57 |

| Machine coVers an area of(m) | 4.29*4.92 | 5.25*4.05 | 5.14*4.75 | 5.5*5.34 | 6.3*4.41 |

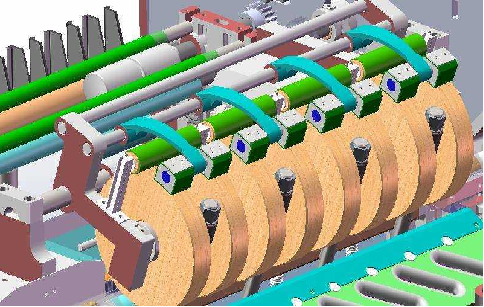

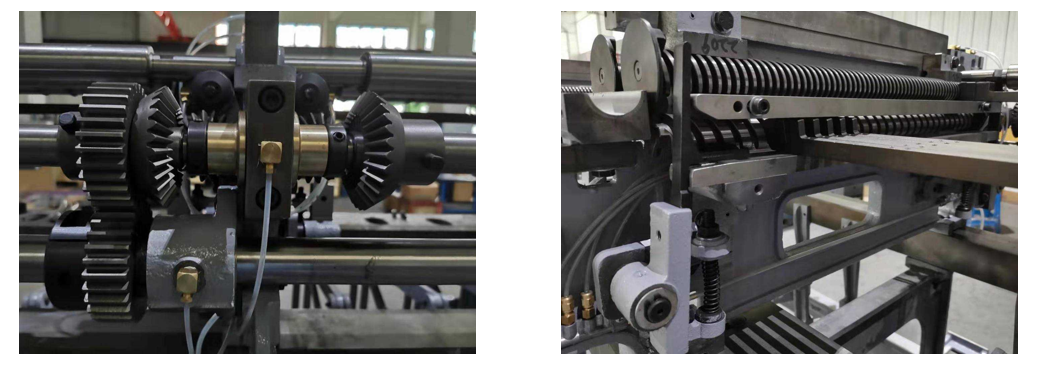

Electro-mechanical Integration

The transmission system is driven by 3 separate motors, the mechanical transmission part is simple, the transmission efficiency is high, the noise is low, and the transmission is stable.

intelligent operation

With the man-machine dialogue interface, the HMI can be used to input all kinds of required process parameters without any change of gears, so the process adjustment is very convenient. Remote management can also be realized. The software is superior to other manufacturers, and can be updated continuously according to customers' requirements. It is convenient to adjust the weight of flax sliver.

Process setting and changing by input parameters on PLC control screen.

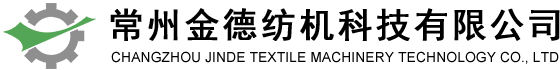

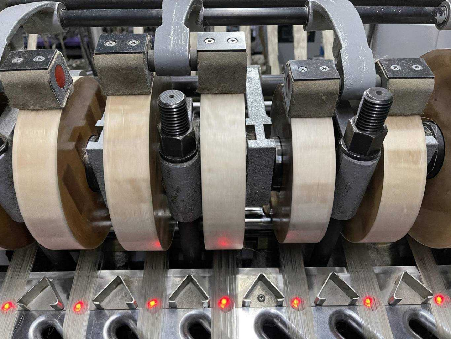

Distinct Coiling and Pressing Design

The structure of coiler and presser adopts rotary pneumatic press mode, which can reduce the mechanical failure and maintenance time, reduce maintenance costs, and make the operation of sliver leading and cans change in front of the machine more convenient

Auto-stop Motion

The front electronic auto-stop motion for yarn breakage added to merging plate (optional) can reduce the labor intensity and manual operation. The reliable structure can reduce the labor intensity and manual operation, and thus can avoid the fiber waste and save the costs.

The Second Cleaning Device on Pressing Roller

The FX280A-FX284A add the second cleaning device that prevents dust and debris from being brought into the finished hemp sliver by rollers after the first dedusting, which improves the quality of the finished hemp and reduces the production of hemp particles.

wood roller second upper cleaning device (optional)

high quality

Superior metallurgy, accuracy processing, stable yarn spinning quality, durable spares maintenance

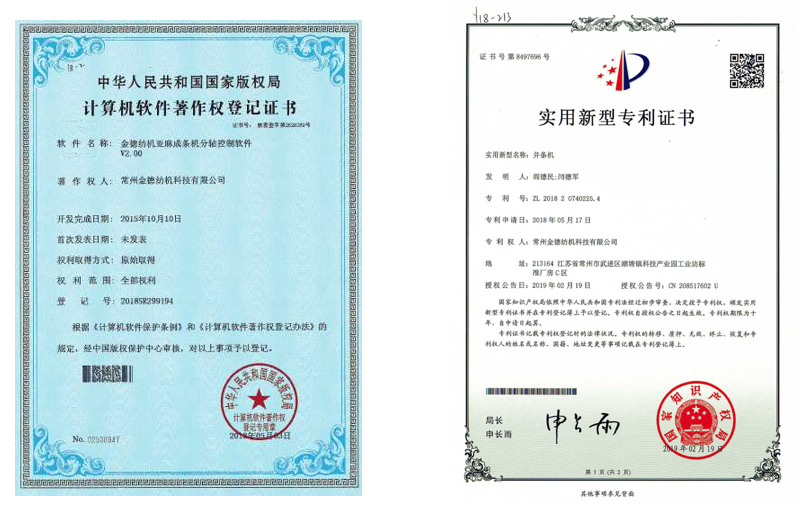

certificates

Recommended Products

Get a Product Quote