FX516 intelligent hemp wet spinning machine

Key words:

Classification:

Product Description

Main Technical Parameters

1 SpindIes 256/320/384 spindIes

2 SpindIe pitch 88mm

3 Winding Cone

4 Lifting EIectronic servo controI

5 Ring pIate stroke 210mm

6 TotaI draft muItipIe 8-30

7 Twist direction Right

8 Drafting mechanism SingIe zone with doubIe apron

9 Draft gauge 155-170( AdjustabIe)

10 Jaw gauge 2-5( AdjustabIe)

11 Diameter of drafting roIIer 50mm

12 Diameter of feeding roIIer 45.4mm

13 Diameter of top roIIer 38mm

14 Diameter of drafting pressure roIIer 78mm (optionaI). bearing type

15 Drafting and feeding pressure CradIe type with spring Ioaded

16 Auto stop MechanicaI push rod

17 Feeding/drafting pressure 25-60 N/cm2 / 50-100 N/cm2

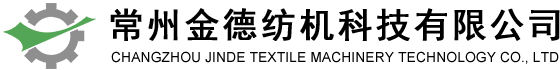

18 Number of motors 4

19 TotaI power 21.4KW/24.9KW

20 Machine size 12500(L)X1580(W)X3450(H)mm(256 SpindIes) 15000(L)X1580(W)X3450(H)mm(320 SpindIes)

Driving System

Drafting Area

The adjustable drafting gauge and uniformly pressured cradle improve the quality

|

|

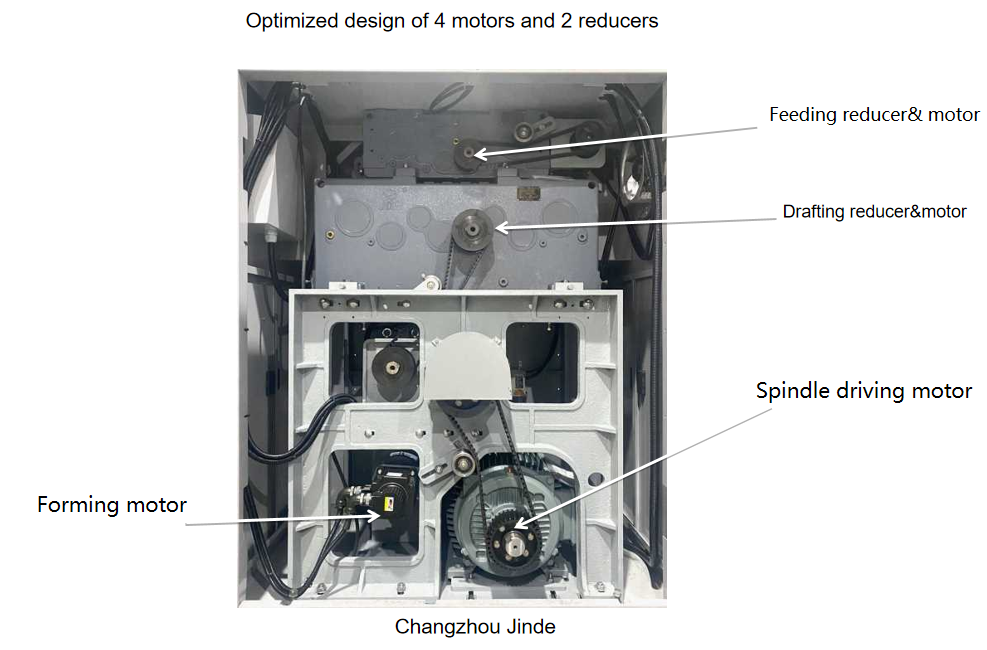

Apron Support

FX516 uses fixed apron frame. In the process of spinning, the speed of the apron in the drafting area remains stable, and the supporting position of the roving sliver does not change, so as to provide good drafting spinning conditions and ensure the quality of the yarn stability. The quick locking device realize the quick disassembly and assembly of the apron frame, which is used for the cleaning work of entangling.

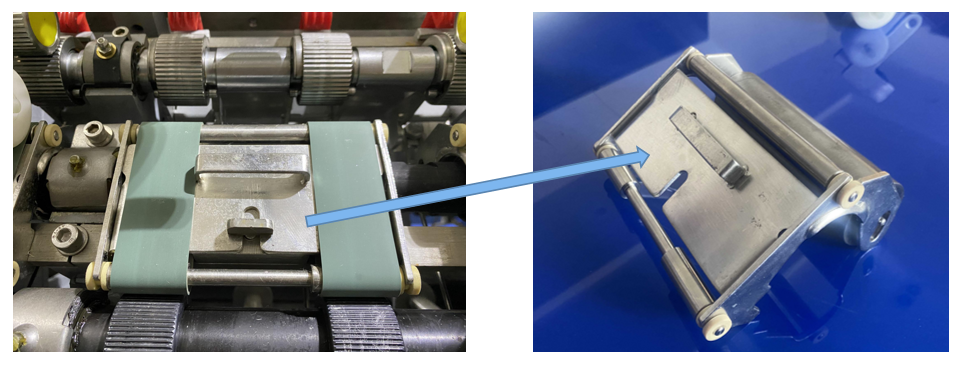

Controlling Roller Bracket

The control roller bracket on FX516 is equipped with two groups of control units, respectively control roller and bottom pin. The structure allows to add control nodes to the roving in the drafting area during spinning. Precise control of roving drafting process ensure even spinning. The non-uniformity is greatly reduced to improve the quality of finished yarn.

Easy Operation

The operator can control the entire mechanical operation process by entering and mornitoring the 4 parameters directly on the screen. With the man-machine dialogue interface, the HMI can be used to input all kinds of required process parameters without any change of gears. The process adjustment is very convenient. Each function can be fine tuned to accurate number and twist. Remote management can also be realized. The software is superior to others, and can be updated continuously according to the requirements of customers

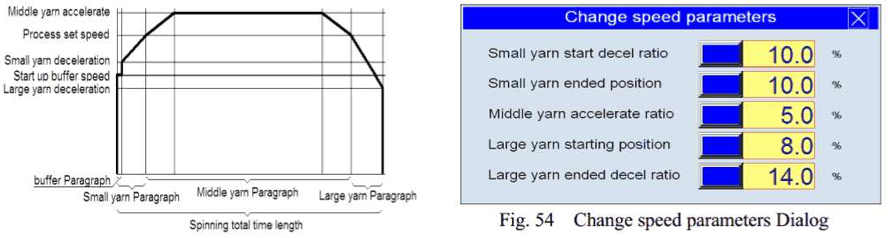

Variable spindle speed curve

Multistage transformation and smooth speed change. Customers can efficiently change spindles speed.

more production low breakage less hairiness

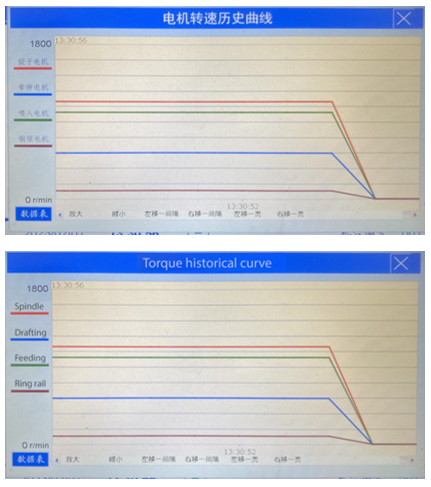

Motor running curve record

Monitoring each motor

Detect fault

24 hours record playback

High Efficiency & High Quality

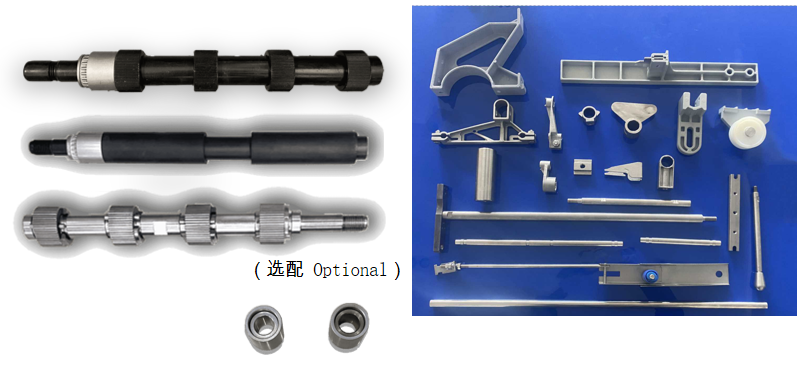

Good metallurgy, with high processing accuracy, a large number of stainless steel parts are used, the daily maintenance cost is low

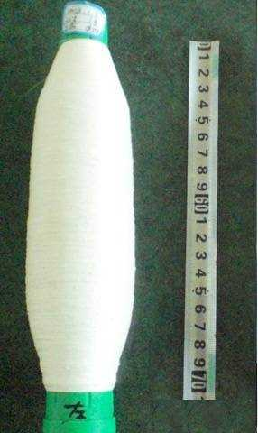

Winding & Forming

Adjustable Forming range helps unwinding, improves auto winding efficiency

While bobbin winding, tight wind in lift up and loose wind in lift down, achieve good yarn drying efficiency and evenness

Customization

The software program allows to spin any special yarn, such as slubby yarn, strong twisting yarn, weak twisting yarn, reverse twisting yarn, and etc. (,which can be customized according to customer demand).

256, 320, 384 spindles can be customized upon user’s request.Customers can also send their request for customization.

Advantages of Ring Frame FX516

1. The head transmission structure is simple and reasonable; low failure rate save the cost on labor and time; low management cost; low the management cost is low. The comprehensive benefit is greatly improved.

2. The drafting area with adjustable distance and pressure significantly improve the spinning quality. The CV% of fine yarn coming out of same roving fibres by FX516 can be increased by 5%, compared to old model. The Uster -50 Index can be approximately decreased by 25%, the +400 can be decreased by 15%.

3. Man-machine interface makes process adjustment very convenient.

4. The software program allows to spin variety of yarn.

5. Spares with high-quality materials and high processing accuracy decrease the daily maintenance cost.

6. Reduce the use of lubricating oil and reduce the noise by about 7 decibels

7. CV is reduced by 1-2%, good evenness and less hairiness; production output is increased by 10-30%, power saving is more than 5-10%; bobbin forming effect is good;winding efficiency is increased by 5-8%.

Recommended Products

Get a Product Quote